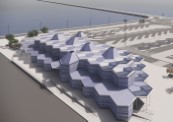

In June of this year, Tarragona Cruise Port embarked on an innovative journey in port infrastructure with the commencement of construction on its new cruise terminal. The construction progress has seamlessly adhered to the planned schedule, showcasing a steadfast commitment to efficiency and punctuality. A significant milestone was reached this week as the emerging structure of the terminal takes visible shape, with pillars rising as witnesses to the project's advancement.

Simultaneously, in Almería, the industrialized manufacturing of the terminal's modules is underway. This methodology is not only a catalyst for efficiency but also a cornerstone for environmental sustainability. Industrialized construction facilitates a notable reduction in material usage, achieving an impressive 50% decrease in waste generation. Furthermore, this approach has led to a 60% decrease in CO2 emissions during the construction phase, with an expected 30% reduction during terminal operation. A significant decrease in water consumption during manufacturing and maintenance, coupled with a 40% reduction in energy usage for climate control, has also been observed.

These statistics underscore the alignment of the project with the ambitious goals of the Sustainability Plan of the Port of Tarragona, particularly in improving waste management within the port community. The substantial reduction in emissions and waste reflects a genuine and practical commitment to environmental sustainability, in line with strategies to optimize water management within the plan.

The evolution of the terminal promises not only to revolutionize the cruise visitor experience but also to establish a new benchmark in sustainability for the port community and beyond. The adoption of industrialized construction at Tarragona Cruise Port terminal brings additional benefits in terms of occupational health and safety. Prefabricating components in a controlled environment in Almería not only enhances construction quality but also minimizes on-site labour risks. This approach provides rigorous control over working conditions, resulting in a significant reduction in accidents and injuries. By limiting the need for work at heights or under potentially hazardous conditions, the project significantly improves personnel safety. These safety measures are a clear indicator of the project's commitment not only to the environment but also to the well-being and protection of its workers, ensuring a safer and healthier working environment.